Primary Metal Manufacturing

The Primary Metal Manufacturing industry is responsible for converting raw metal ores into usable metal forms, such as steel beams, aluminum sheets, and copper wiring. This sector includes smelting, refining, casting, and rolling processes that transform raw materials into high-quality metal products used in construction, manufacturing, and transportation. Companies in this industry play a vital role in providing foundational materials for various economic sectors.

Number of Workers in North America in 2023

541,000 Workers

Number of Accidents in North America in 2023

17,700 Accidents

Safety Solutions

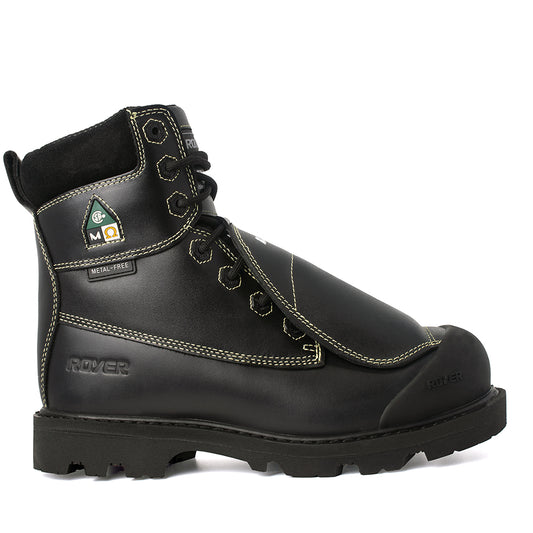

Steel mills, foundries, and metal processing facilities expose workers to some of the most hazardous industrial conditions, including extreme temperatures, molten metal splashes, and airborne particulates. Without the right protection, burns, respiratory hazards, and crushing injuries are serious risks. We engineer safety solutions that withstand the rigors of metal processing, from heat-reflective materials to reinforced impact zones. Learn how our protective innovations help keep workers safe in extreme manufacturing environments.

Risk of Impacts or heavy falling objects

The risk of impacts or falling objects refers to the potential for direct impacts on the foot, including incidents involving falling objects, collisions with moving machinery, and handling heavy tools, equipment, or objects.

Our safety toe cap options provide robust protection against impact and compression hazards.

- Composite Toe Cap: Lightweight and metal-free, offering certified protection against impact and compression while preventing electrical conductivity.

- Steel Toe Cap: Traditional and highly durable, providing certified safety protection against impact and compression.

- Aluminium Toe Cap: Lightweight with a slimmer profile than the traditional steel toe cap, it offers certified safety protection against impact and compression.

- NANOTOE®: Lightweight and robust, it is made from carbon nanotubes offering certified protection against impact and compression.

- PARESHOK™: Positioned over the protective toecap for added durability, increasing the vamp's wear resistance.

Related Certifications

Protective Toecap

(CSA

Z195-14) Certified grade 1 protective toecap that withstands impacts up to 125 joules

Protective Toecap & Puncture-resistant Sole

(CSA

Z195-14) Certified grade 1 protective toecap that withstands impacts up to 125 joules and certified puncture-resistant sole that withstands at least 1200 Newtons (270 pounds)

Our metatarsal protection solutions are designed to shield the top of the foot from heavy impacts and crushing forces.

- REALFLEX™: Our certified traditional external metatarsal guard protects against impacts and heavy falling objects while allowing natural movement.

- INTERGUARD®: Our certified first-generation flexible internal metatarsal guard enhances comfort and mobility while offering certified protection against impacts and heavy falling objects.

- INTERGUARD® 2.0: Our certified second-generation internal metatarsal guard, developed through five years of research to provides high-impact certified protection without compromising comfort.

Related Certifications

Metatarsal Protection

(CSA

Z195-14) Certified metatarsal protection that can withstand impacts up to 101.7 joules

Risk of Cuts

The risk of cuts involves the potential for injury from sharp or pointed objects, such as when handling metal, glass, cutting tools, or machinery with sharp edges.

Our cut-resistant materials offer exceptional durability and protection against sharp objects while maintaining flexibility and breathability.

- SHIELDTEX™: High-performance abrasion-resistant fabric originally developed for the car and motorcycle racing industry, offering superior cut resistance.

- CORDURA®: High-performance textile known for its exceptional durability and resistance to cuts, abrasion, and wear.

Our reinforced materials provide exceptional cut resistance while offering additional durability and heat resistance.

- KEVLAR™: This reinforced threading withstands extreme heat, resists burning, melting, and degradation under intense temperatures, while also offering superior cut resistance, flexibility, and durability.

- K2™ KEVLAR™: This high-strength reinforced threading is 2.5x stronger than nylon or polyester, delivering advanced cut resistance while offering heat resistance up to 800°F (427°C).

Risk of Punctures

The risk of puncture refers to the potential for sharp objects to pierce the sole or upper of footwear, with possible injury from hazards such as nails, metal fragments, glass shards, and ground debris.

Our puncture-resistant soles provide a critical barrier against sharp objects, resisting penetration through the sole of the boot while maintaining comfort and flexibility.

- Steel Plate: A rigid and highly durable solution offering maximum puncture protection against sharp objects. Ideal for environments with high exposure to nails, metal shards, and other piercing hazards.

- Composite Plate: A lightweight, flexible, and metal-free alternative to steel, offering high puncture resistance while maintaining electrical insulation. Designed to reduce foot fatigue, it is ideal for work environments requiring non-metallic footwear.

Related Certifications

Protective Toecap & Puncture-resistant Sole

(CSA

Z195-14) Certified grade 1 protective toecap that withstands impacts up to 125 joules and certified puncture-resistant sole that withstands at least 1200 Newtons (270 pounds)

Risk of Heat Exposure

The risk of heat exposure involves the danger of high-temperature conditions causing burns, thermal stress, or degradation of protective footwear, particularly in environments with radiant heat, molten materials, or open flames.

Heat-resistant materials protect against extreme temperatures, preventing burns and reducing thermal transfer.

- KEVLAR™: This reinforced threading withstands extreme heat, resists burning, melting, and degradation under intense temperatures, while also offering superior cut resistance, flexibility, and durability.

- K2™ KEVLAR™: This high-strength reinforced threading is 2.5x stronger than nylon or polyester, delivering advanced cut resistance while offering heat resistance up to 800°F (427°C).

Certified for safety and performance

Meeting the Highest Industry Standards with Proven Expertise

At ROYER®, safety is paramount. Our safety boots and shoes meet stringent safety standards through rigorous laboratory testing to ensure compliance with industry requirements. We test performance every 500 pairs within the same certification group to maintain consistent safety and quality standards.

CSA Z195

Our products are certified by the Canadian Standard Association (CSA) under the Z195 “Protective Footwear” Standard. Tests are carried out systematically on all our production to ensure continued compliance with the Z195 standard and ensure the highest level of quality.

ASTM F2413

Our products are certified according to ASTM (American Society for Testing and Materials) F2413 standard, which covers the minimum design, performance, testing, labeling and classification requirements for safety footwear.

The royer Audit services

The perfect fit between product and environment

Maximize safety and performance in your workplace with our comprehensive ROYER® Audit Service. We assess your unique working environment to ensure the right footwear for every job. Our audit covers five key areas:

1

Risk and Hazard Assessment

Identify and prioritize workplace dangers.

2

Environmental Conditions

Analyze climate factors for the best material choices.

3

Ergonomics and Comfort

Ensure optimal protection and comfort based on worker movements.

4

Industry Standards

Meet all local and international safety regulations.

5

Durability and Maintenance

Choose long-lasting, low-maintenance footwear.

Book an Audit Today

Thank you for filling out the form! You will receive a confirmation email.