We Are Work Boots

Lac-Drolet

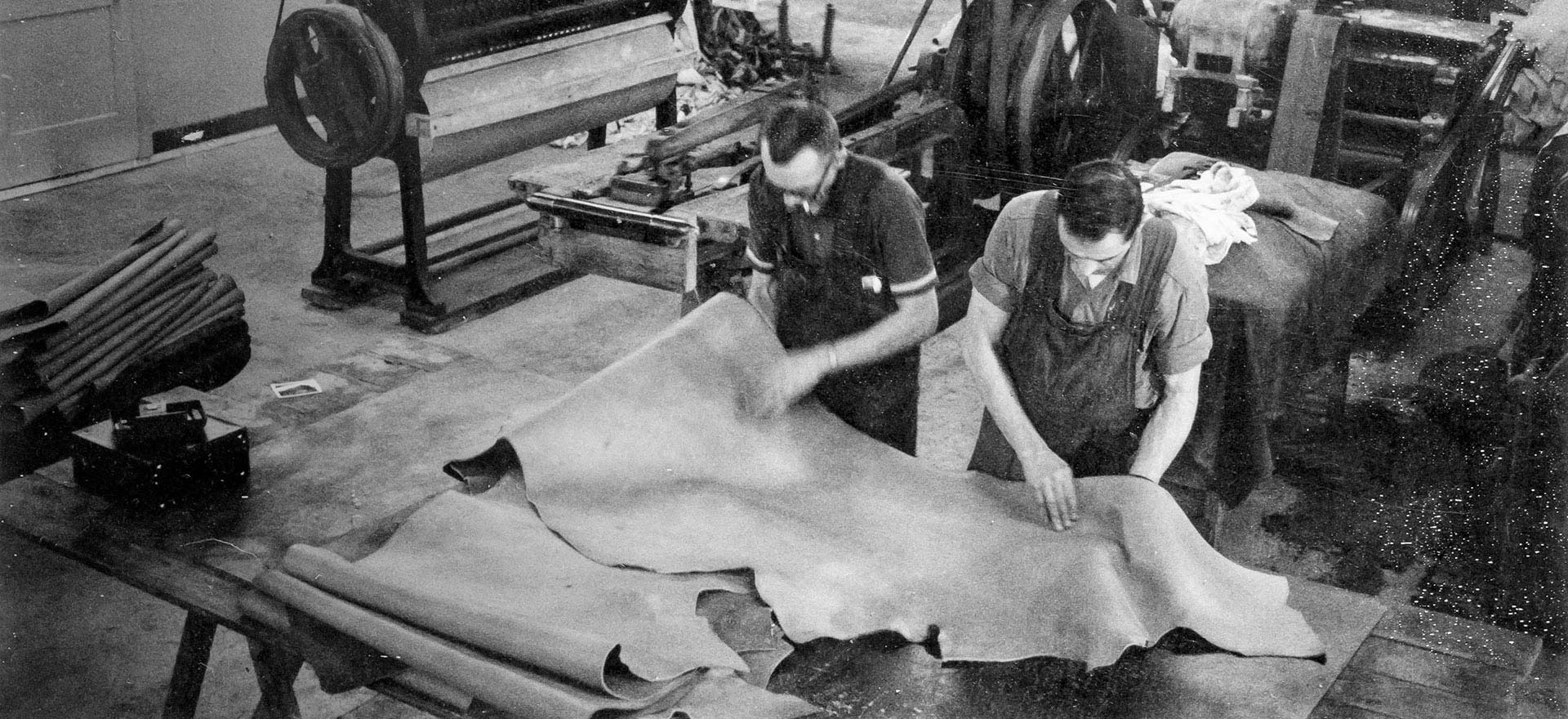

Royer was founded in Lac-Drolet in 1934. Today, the Lac-Drolet manufacturing plant specializes in the vulcanization of thermosetting rubber. The XPAN® process enables the manufacture of dual-density rubber soles and offers robust boot construction for the most extreme environments, including primary metal processing.

Sherbrooke

Inaugurated in 2019, the Sherbrooke plant specializes in polymerization. A process of injecting polyurethane directly into the upper enables the manufacture of lightweight, flexible and comfortable boots for a wide variety of sectors, including construction, industrial manufacturing and transportation.

Magog

Inaugurated in 2024, the Magog plant specializes in high-performance thermoplastic elastomers (TPR). The Magog plant manufactures waterproof boots resistant to a variety of chemical and biological products for agriculture, mining and gas extraction, food processing and other sectors requiring a high level of protection.

NEW COLLECTION COMING SOON

Respect is ROYER’s core value – Respect for our customers, respect for our products and respect for those who contribute to making them. We believe in doing the right thing by keeping our promises, and by delivering top-quality products.

Rigor, discipline and attention to detail and precision result in products that truly perform. We are proud of each pair of boots that bears our name and believe that the best way to demonstrate this pride is through the quality of our work, from the product’s design down to its very last stitch.

Maintaining the “status quo” is not an option – we aim for excellence. And achieving excellence requires hard work, persistence, and commitment. As creators of ideas and initiators of change, we constantly strive to achieve the impossible. We never shy away from going the extra mile and thinking outside the box.

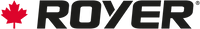

Since 1934, we have designed and manufactured high-performance safety footwear for a wide range of work environments, from conventional settings to the most demanding conditions.

The performance of ROYER® products is based on a disciplined development approach where the analysis of the sector, the occupation, the work environment, and the needs of the worker are at the heart of our concerns.

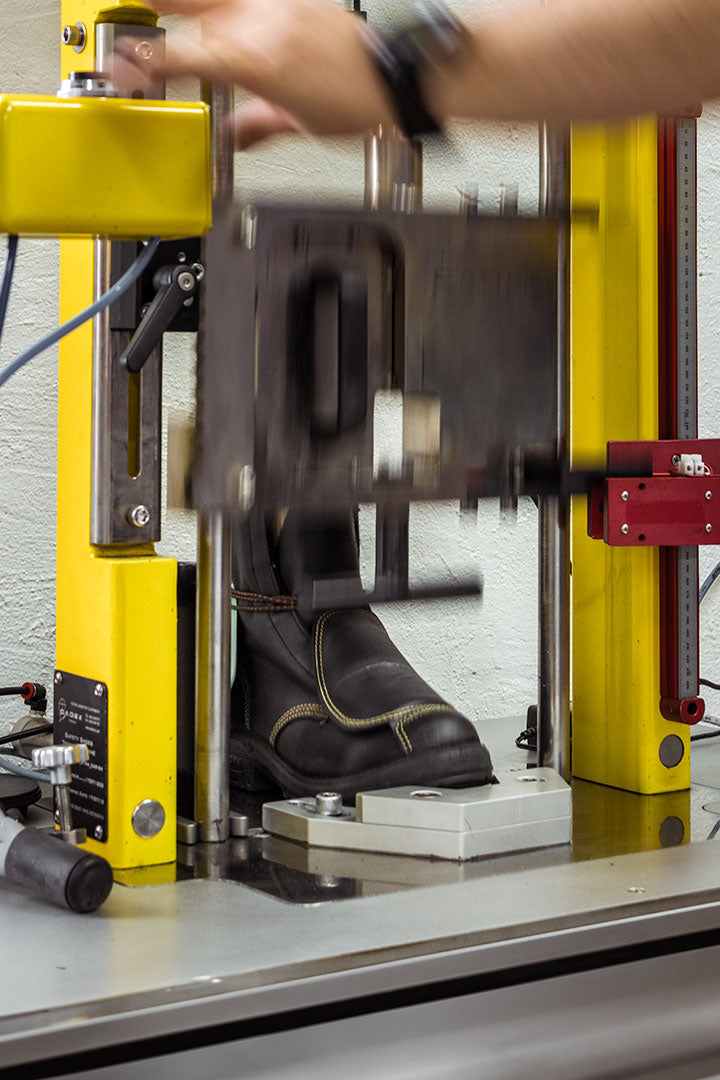

To ensure exceptional product performance, we work closely with independent research centers. The materials and components used in our boots undergo rigorous testing, as do the boots themselves. Key properties such as slip resistance, breathability, thermal insulation, waterproofing, flexural endurance, chemical resistance, and shock absorption are carefully and methodically evaluated.

In addition to laboratory testing, we conduct validation tests in real-world environments. These field tests are the benchmark for performance and crucial to driving innovation. By collaborating directly with industrial users, we elevate protection, comfort, durability, and performance—ensuring our products exceed the demands of the toughest work environments.

It takes approximately 120 manufacturing steps to produce a safety boot. During each of these steps, our teams and partners ensure that the elements of durability, protection, comfort, and design reflect the ROYER standard.

CERTIFIED FOR SAFETY AND PERFORMANCE

Meeting the Highest Industry Standards with Proven Expertise

At ROYER®, safety is paramount. Our safety boots and shoes meet stringent safety standards through rigorous laboratory testing to ensure compliance with industry requirements. We test performance every 500 pairs within the same certification group to maintain consistent safety and quality standards.

CSA Z195

Our products are certified by the Canadian Standard Association (CSA) under the Z195 “Protective Footwear” Standard. Tests are carried out systematically on all our production to ensure continued compliance with the Z195 standard and ensure the highest level of quality.

ASTM Z2413

ASTM: Most of our products have been approved under the American ASTM (American Society for Testing and Materials) standard for safety footwear and feature the labeling required by this organization (standards F2412-11 and F2413-11).